Signed in as:

filler@godaddy.com

Signed in as:

filler@godaddy.com

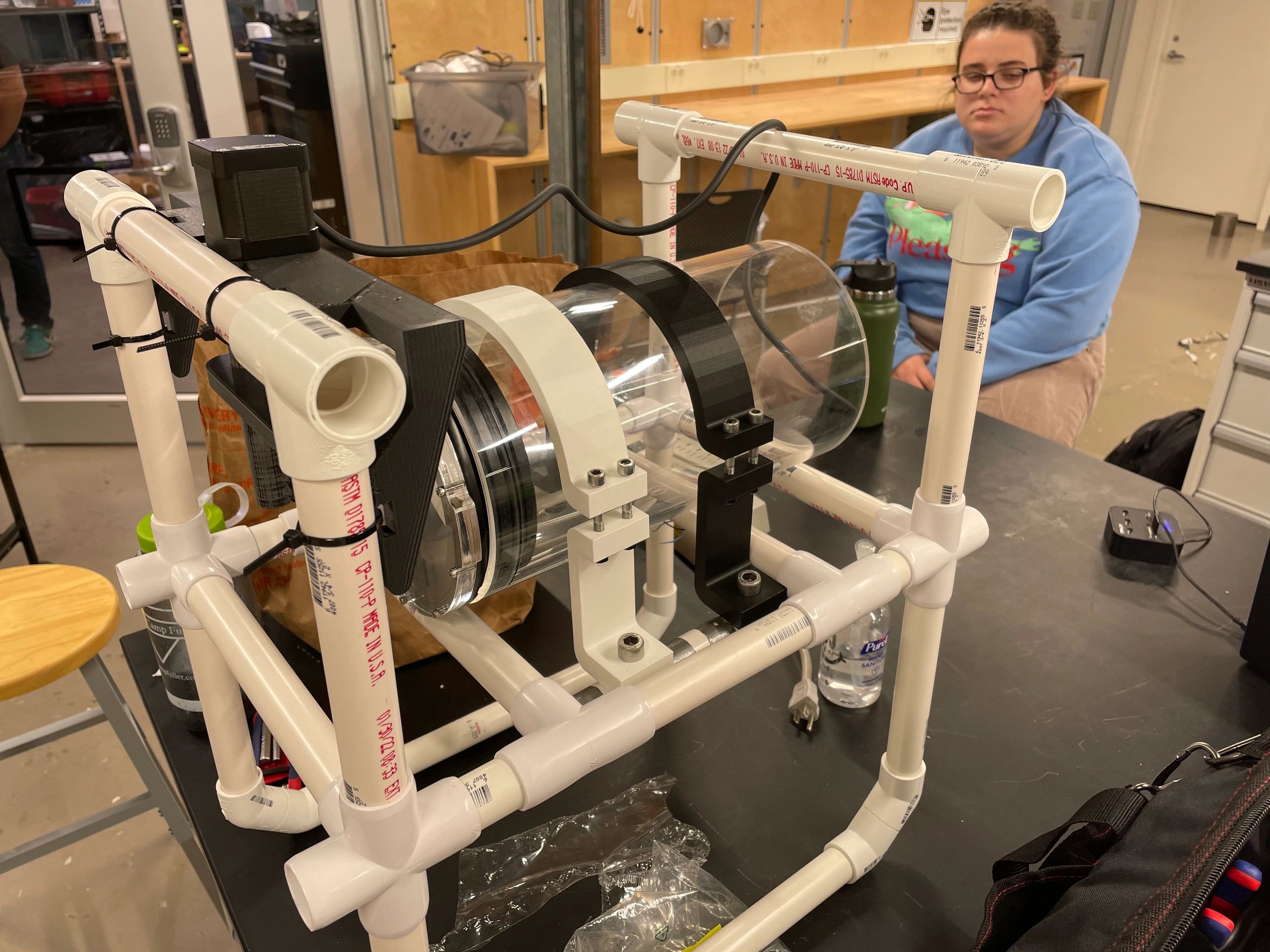

I was part of Northeastern's Underwater Robotics Club, where my main focus was figuring out how to design and implement the arm of the robot.

I was tasked with helping to designing the arm of an underwater robot that had full rotational and linear motion.